Quality Control

Effectively and reliably verifying the required cleanliness is an important aspect of quality control. Of course, we include reliable documentation in our services, and can evaluate components with a variety of methods:

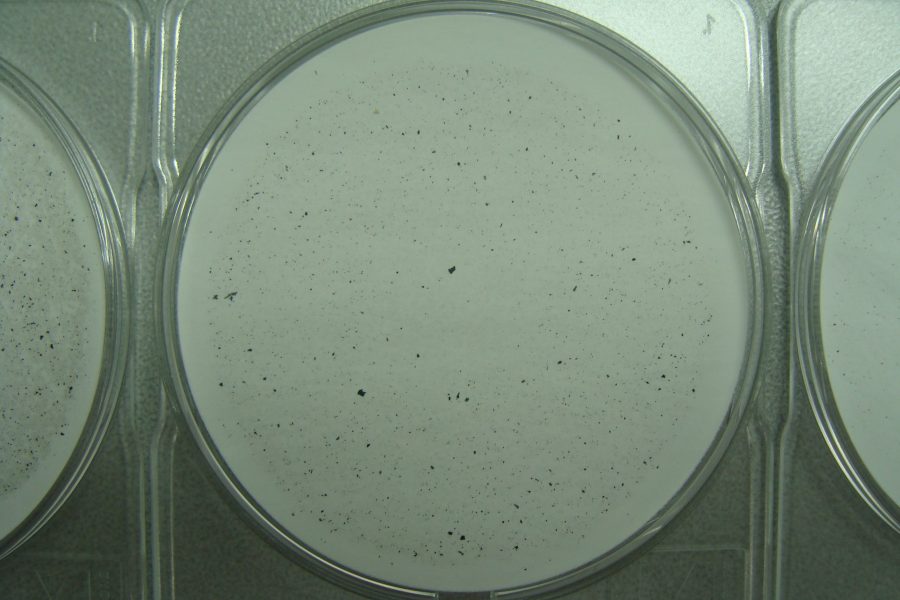

Residual-dirt analyses

Our laboratory can perform high-quality analyses for you in accordance with VDA Volume 19 (ISO 16232) or to customer standards cost-efficiently. No matter whether you are looking for in-process cleaning in combination with cleaning in our parts cleaning centre, or for a standalone service: we offer gravimetric analysis, particle size distribution from 5 microns onwards, decay measurement, surface tension, and residual magnetism determination.

Surface energy

Surface energy measurement is known to the industry as a tried-and-tested, simple inspection method. For this purpose, the surface of the cleaned component is wetted with different test liquids of defined surface tensions. The subsequent observation period shows whether the surface tension in mN/m is been reached or not. Our inks are always applied with sterilised cotton swabs to prevent contamination.

Visual inspection

If desired, we can perform a full visual inspection of your components. We will require a fault catalogue in this case.