Combined Chamber Systems

If your cleaning system has to meet a variety of requirements and handle both polar and nonpolar contamination, a combined cleaning system often is the best choice.

We use several working chambers in chamber systems in this case. vapic technology includes dewatering after the aqueous pre-cleaning as a special feature in this area, dispensing with the step of intermediate drying.

The number of working chambers and the unit size can be customised to match the desired cycle time.

We can customise the cleaning step sequence to your needs as well.

Advantages of combined cleaning:

- Use of dewatering.

- Optimised cycle time.

- Removes of different types of contamination.

- Quick and reliable vacuum drying.

Find a small selection of the vapic technology options below:

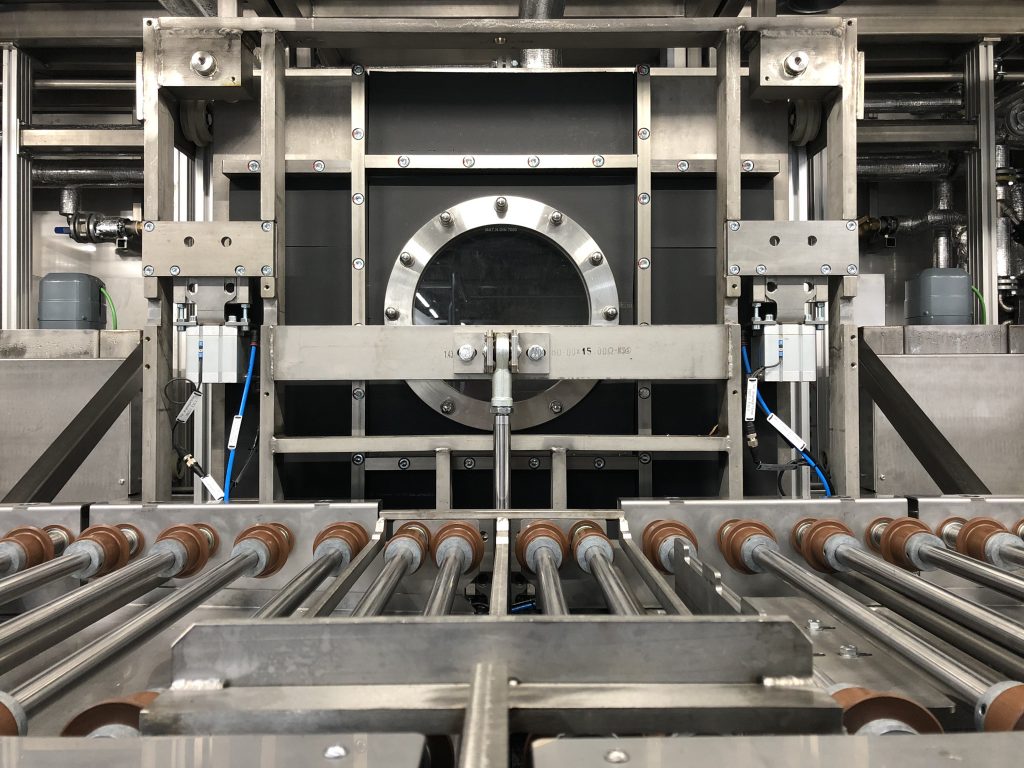

vapic Alternating Pressure

Alternating pressure in the working chamber shifts the boiling point to make the cleaning agent oscillate between boiling and condensation. This method is proven to amplify the rinsing effect, in particular in small blind holes(Ø < 6 mm) since the fluid forms vapour bubbles at low pressure that implode in turn as pressure increases. This ensures a powerful cleaning agent exchange even in more complicated component geometries. Alternating pressure can be used with solvents and with rinsing baths for aqueous cleaners alike.

Energy-Saving Technology

Dry-running vacuum pumps are at the core vapic energy cycle. The compression and condensation energy applied is preserved by smart circulation, to be reused for the process, saving an enormous share up to up 50% of the energy previously required. Our technology knowledge brings about unique processes for best cleaning results even on the most complicated components. Our parts cleaning systems offer high quality, effective cleaning, and immense efficiency.

Dewatering

Aqueous pre-cleaning is followed by the “dewatering” process step to keep all water out of the solvent process. No intermediate drying is required.

Vacuum Infrared Drying

All parts can be vacuum dried with our infrared system that renders the energy stored in the part irrelevant. This method achieves subsequent thermal cleaning for many types of contamination.

We are the only manufacturer to offer this technology for use with solvents.